A Johnny Joint is a type of mechanical joint used in a variety of applications. It is a strong, reliable, and resilient joint that can be used in many applications. The Johnny Joint is a popular choice for off-road applications, as it is designed to absorb shock and vibration and is resistant to corrosion and wear.

Table of Contents

READ: Best Suspension Kits: A Comprehensive Guide

The Structure of a Johnny Joint

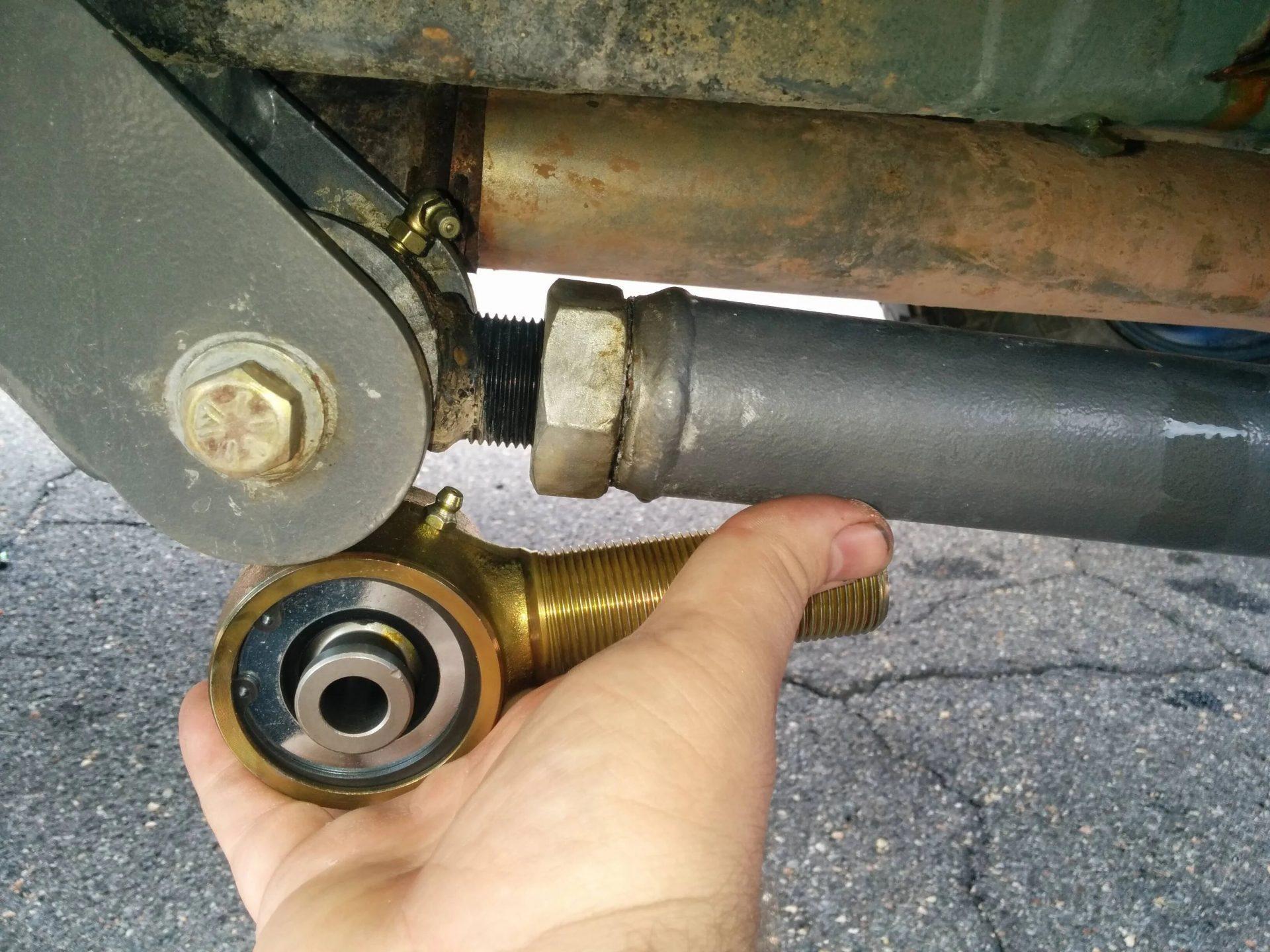

The Johnny Joint comprises two main components: the body and the pin. The body is a round, cylindrical piece of metal with a cylindrical hole in the center. The pin is also made of metal and is inserted into the hole in the body. The pin is held in place by two C-rings, which are placed over the pin and secured with a bolt.

The pin is also connected to a spring designed to absorb shock and vibration and is connected to the body. This combination of components creates a strong, reliable, and resilient joint.

Advantages of the Johnny Joint

The Johnny Joint has several advantages over other types of mechanical joints. First, it is designed to absorb shock and vibration, which makes it well-suited for off-road applications. Second, the joint is resistant to corrosion and wear, which makes it a good choice for long-term use.

Finally, the joint is relatively easy to assemble, which makes it a popular choice for many applications.

Applications of the Johnny Joint

The Johnny Joint is used in many different types of applications. It is commonly used in off-road vehicles, such as four-wheelers, ATVs, and dirt bikes, as it is designed to absorb shock and vibration. It is also used in industrial applications, such as to connect hydraulic cylinders, as it is solid and reliable.

In addition, it is often used in robotics and automation applications, as it can be easily assembled and disassembled.

READ: Can Old Vehicles Be Converted Into Electric Vehicles?

Pros and Cons of the Johnny Joint

The Johnny Joint has both advantages and disadvantages. On the plus side, it is solid, reliable, and designed to absorb shock and vibration. On the downside, it is relatively expensive compared to other mechanical joints. In addition, it is not as easy to disassemble as some other types of joints.

Benefits Of A Johnny Joint

The primary benefit of a Johnny Joint is its superior level of articulation. This allows the joint to move in multiple directions, providing a more excellent range of motion and flexibility than traditional suspension joints. Additionally, the Johnny Joint is designed with a unique combination of steel and rubber components, making it highly durable and able to withstand the rigors of off-road and racing conditions.

Finally, the joint is designed to be strong, with a high degree of strength and stability. This allows it to provide superior performance in even the most challenging conditions.

Off-Road Applications

The superior articulation, durability, and strength of a Johnny Joint make it ideal for off-road applications. It can be used in suspension systems for off-road vehicles, providing superior articulation and performance.

Additionally, the Johnny Joint can be used in various off-road applications, such as steering linkages, sway bars, and other suspension components. The joint is also highly resistant to corrosion, making it an excellent choice for off-road applications where it may be exposed to harsh conditions.

Racing Applications

The Johnny Joint is also becoming increasingly popular in the world of racing. Its superior articulation, durability, and strength make it an ideal choice for racing applications. It can be used in the suspension systems of race cars, providing superior performance and greater flexibility. Additionally, the joint is highly resistant to corrosion, making it a great choice for racing environments where it may be exposed to harsh conditions.

Installation and Maintenance

The Johnny Joint is relatively easy to install and maintain. It typically requires only essential tools and minimal effort to establish. Additionally, the joint requires minimal maintenance and can easily be adjusted to ensure optimal performance. This makes it an ideal choice for off-road and racing applications, where performance and reliability are essential.

Cons of A Johnny Joint

The Johnny joint is popular due to its flexibility, strength, and ability to absorb shock. However, some cons to using a Johnny joint must be considered before making a decision.

Wear and Tear: The Potential for Damage

One of the primary cons of a Johnny joint is the potential for wear and tear. Due to its flexibility, the joint can be subject to more stress and strain than other types. This can lead to the joint becoming damaged or worn down over time, resulting in decreased performance and reliability. Additionally, if the joint is not properly lubricated, the wear and tear can be even more severe.

Increased Difficulty in Installation: The Need for Precision

Another con of a Johnny joint is the increased difficulty in installation. When installed, this type of joint requires precision and accuracy, as even the slightest misalignment can lead to excessive vibration and premature failure. Furthermore, the bolts and other components must be tightened to the prescribed torque rating to ensure that the joint is securely fastened and can withstand the loads it will be subject to in its operational environment.

Risk of Corrosion: The Need for Protection

The risk of corrosion is another con associated with using a Johnny joint. This type of joint is usually made from high-strength steel, which is susceptible to corrosion when exposed to harsh environmental conditions. Therefore, it is essential to take the necessary steps to ensure that the joint is adequately protected against corrosion. This may include applying a protective coating or using a corrosion-inhibiting lubricant.

READ: Do Electric Vehicles Have An AC?

Conclusion

The Johnny Joint is a popular mechanical joint used in many applications. It is robust, reliable, and designed to absorb shock and vibration, which makes it well-suited for off-road and industrial applications. In addition, it is relatively easy to assemble, which makes it a popular choice for many applications.

However, it is relatively expensive compared to other mechanical joints, and it is not as easy to disassemble as different types of joints.