The Cost of Converting a Gasoline Engine to Electric

By Sebastian Orellana

Updated Feb 17, 2024

Converting a gasoline engine to electric power is becoming increasingly popular for those looking to reduce emissions and save on fuel costs. The cost of converting a gasoline engine to an electric one varies significantly depending on the type of engine being restored, the components being used, and the labor involved.

Table of Contents

In this post, we will explore the cost of converting a gasoline engine to an electric one and provide a breakdown of the costs to consider.

READ: How Much Does It Cost to Convert an Old Car to EV?

Types of Engines

The first factor in determining the cost of converting a gasoline engine to electric is the type of engine being converted. There are two main types of gasoline engines: internal combustion engines (ICE) and external combustion engines (ECE). The most common type of ICE is the spark-ignition engine, which is used in most passenger cars and light trucks.

The most common type of ECE is the steam engine, used in heavy-duty vehicles and boats. The type of engine being converted will influence the conversion cost, as the components used and labor required will differ depending on the engine type.

Components

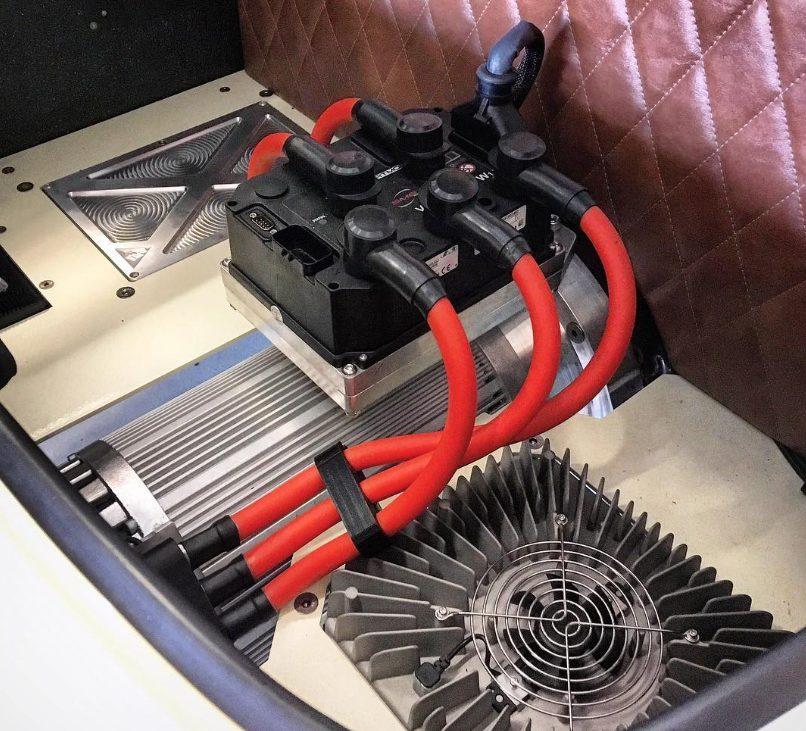

The components used are the second factor in determining the cost of converting a gasoline engine to an electric one. The details required for a successful conversion will vary depending on the type of engine being restored. Still, some standard components include an electric motor, battery, charging system, wiring, and an electronic control unit.

The cost of these components can range from several hundred to several thousand dollars, depending on the quality and type of parts used.

Labor Requirements

The labor required is the third factor in determining the cost of converting a gasoline engine to electric. The work required will depend on the conversion's complexity and the mechanic's experience. Complex modifications may require specialized knowledge and experience, so the cost of labor can become quite expensive.

Most modifications will require at least 10-20 hours of work, depending on the type of engine being converted and the mechanic's experience.

Additional Costs

In addition to the cost of the components and labor, several additional costs are associated with converting a gasoline engine to electric. These costs include the cost of disposing of the old gasoline engine, as well as any other parts and accessories needed for the conversion. Depending on the type of engine being converted, additional costs may include the cost of an electric cooling system, an electric fuel pump, and other components.

READ: What is Needed to Convert a Car to Electric?

Cost of Conversion

The total cost of converting a gasoline engine to an electric one will depend on the type of engine being restored, the components being used, and the labor required. Generally speaking, converting a gasoline engine to an electric can range from several hundred to several thousand dollars.

Benefits

Although the cost of converting a gasoline engine to an electric one can be pretty expensive, the benefits of the conversion far outweigh the cost. Converting a gasoline engine to an EV can significantly reduce emissions, as electric motors are much more efficient than gasoline engines. Additionally, electric engines are quieter and require less maintenance than gasoline engines, which can save on fuel costs over the long term.

Considerations

When considering the cost of turning a gasoline engine to an EV, it is essential to consider the long-term benefits of the conversion. Although the initial cost of the conversion may be pretty expensive, the long-term savings in fuel and maintenance costs may make the conversion worth the investment. Additionally, it is important to consider the quality of the components being used and the experience of the mechanic performing the conversion.

Components

The components needed play a significant role when it comes to the cost of making a gasoline engine to EV. The details required to complete the conversion include the electric motor, battery, and electronic control unit. Depending on the size of the engine and the vehicle, the price of the components can range from around $3,000 to more than $10,000.

Labor and Installation

Though the cost of the components can be significant, the cost of labor and installation can be even higher. The cost of delivery and installation typically ranges from $1,500 to $3,000. This cost can vary depending on the job's complexity and the mechanic's expertise.

Potential Savings

Though converting a gasoline engine to an electric one can be expensive, the potential savings can be even more significant. Electric vehicles can save drivers thousands of dollars each year in fuel costs. Additionally, electric cars are much more efficient than gasoline-powered vehicles, reducing emissions and helping to protect the environment.

Tax Credits

Sometimes, drivers may be eligible for tax credits when converting their vehicles to electric. Depending on the state, drivers may be eligible for up to a $2,500 tax credit. This tax credit can help offset some of the conversion costs.

DIY Conversion

Mechanically inclined drivers may choose to do the conversion themselves. Though a DIY conversion can save money, it is not recommended for those without experience. Additionally, DIY conversions are not eligible for tax credits.

READ: Cost Comparison: DIY EV Conversion Kits Vs. Professional Installation

The Cost of Converting a Gasoline Engine to Electric - Conclusion

In conclusion, converting a gasoline engine to electric can significantly reduce emissions and save on fuel costs over the long term. The conversion cost will vary considerably depending on the type of engine being converted, the components being used, and the labor required. When considering the conversion cost, it is important to consider the long-term benefits, the components' quality, and the mechanic's experience.