Impact of Battery Technology on EV Pricing

By Sebastian Orellana

Updated Feb 17, 2024

In this article, we delve into the critical role of battery technology in the evolution and pricing of electric vehicles (EVs). We explore different types of battery technologies and discuss their cost implications for both manufacturers and consumers. The article also highlights how advances in battery technology have influenced EV pricing over time, providing real-world case studies from companies like Tesla and GM.

Table of Contents

Further, we examine the impact of battery lifespan and performance on cost and the effect government policies and market forces have on this dynamic sphere. The broader impact of battery technology innovations on the global EV market is also addressed. This comprehensive guide examines the intricate interplay between battery technology and EV pricing.

READ: How To Build Your EV Into A High-Performance Electric Car?

Relevance of Battery Technology to EVs

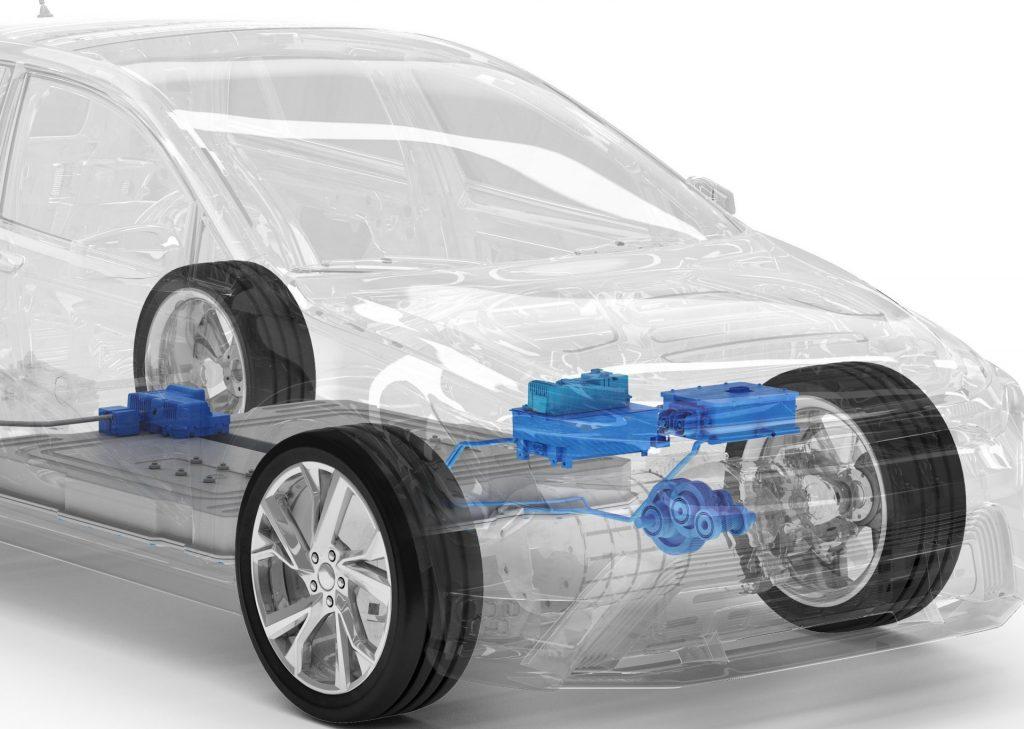

In electric vehicles (EVs), the battery is their central component. Each interplay between the vehicle and its environment—whether in motion, at rest, charging, or discharging—impinges upon and is influenced by the battery's state. Therefore, electric vehicle design and performance are dictated mainly by battery technology. In this section, we shall explore the significance and implications of battery technology for electric vehicles.

Understanding the Critical Role of Batteries in EVs

The importance of the battery in an electric vehicle cannot be overstated. The battery's role is twofold; it is the vehicle's energy source and storage system. Unlike conventional cars, which generate energy through gasoline combustion, electric cars draw power directly from their batteries. This battery-powered operation eliminates the need for a fuel system, reducing the vehicle's ecological footprint and improving efficiency.

These batteries, therefore, must be capable of storing and releasing energy reliably and efficiently. They must also be durable and safe, able to withstand the physical stresses encountered in driving conditions and resist spontaneous combustion or leakage of hazardous materials. Furthermore, these batteries should ideally be lightweight (to minimize the energy required to move the vehicle) and cost-effective (to keep the price of the vehicle within reach of potential buyers).

Battery Technology: The Heart of Electric Vehicles

Different types of batteries employ various technologies to store and release energy. Lithium-ion technology is today's EVs' most prevalent form of battery technology. These batteries are lightweight, rechargeable, and capable of storing more energy than their size and weight - all qualities which make them ideal for electric vehicle use.

However, lithium-ion batteries are not without their drawbacks. Care must be taken to avoid overcharging, leading to rapid performance degradation. They are also relatively expensive to produce and rely heavily on lithium, a finite resource with an increasingly volatile market.

Looking to the future, other types of battery technology, such as solid-state batteries, are under development. These promise to deliver improved energy density and safety parameters by eliminating the liquid electrolyte found in lithium-ion batteries. However, they are currently limited by challenges in manufacturing and cost-effectiveness.

Brief History of EV Battery Technology

Modern electric vehicles, powered by advanced lithium-ion batteries, can feel like a recent innovation. However, the history of EV battery technology has its roots in the early days of the automotive industry, when lead-acid batteries granted the first electric vehicles their modest ranges and speeds.

In the following decades, various kinds of battery technologies surfaced and were gradually displaced as more effective alternatives came along. Nickel-cadmium batteries (NiCad), followed by nickel-metal hydride batteries (NiMH), and eventually lithium-ion batteries, entered the scene. Each generational shift in battery technology improved efficiencies and expanded electric vehicle design and performance possibilities.

Battery technology is key to electric vehicles' functionality, performance, and achievable range. Advancements in battery technology can lead to more efficient, safer and more affordable electric vehicles and increase the feasibility of a wider transition towards sustainable transportation. The evolution of EV battery technology is an exciting field in which many innovative breakthroughs are expected shortly.

Battery Technology Types and Their Costs

Batteries play a pivotal role in a variety of sectors. For instance, batteries are integral in the automotive industry's Electric Vehicles (EVs). The battery technology employed in such situations depends on cost-effectiveness, weight, durability, and overall performance. In this discussion, we delve into the types of batteries commonly used today along with the associated costs.

Popular Battery Technologies Used in EVs

A handful of battery types tend to dominate in their application in Electric Vehicles, primarily due to their efficiency in both cost and performance. Lithium-ion batteries are one of the most commonly used battery types in EVs. Lithium-ion batteries have a high energy density and a relatively low self-discharge; they are also generally light-weight, making them an optimal choice for EVs.

Another popular battery technology is the Nickel-Metal Hydride (Ni-MH) battery, which balances cost and performance well. Ni-MH batteries have a moderate energy density and are known for their longevity and stability.

The Lead-Acid battery, while a more mature technology, still finds use in some EVs. These batteries are low-cost and have a high surge current capability. Still, the low energy density and shorter lifespan compared to other battery types put them at a disadvantage.

Cost Implications of Different Battery Technologies

As mentioned, the cost of a battery plays a crucial role in its application in EVs and other sectors, and different battery technologies come with their cost implications. For instance, while Lithium-ion batteries offer immense benefits in terms of energy density and weight, their manufacturing process tends to be costly. Part of this cost is due to the need for safety features; lithium-ion batteries are notorious for combusting if mishandled or if there is a manufacturing defect.

On the other hand, Ni-MH batteries tend to be less costly than Li-ion batteries, but they cannot match the latter's energy density or lightweight. Lead-acid batteries are the most cost-effective, but their heavy weight and lower life expectancy limit their usability in EVs and similar applications. Therefore, while considering battery technology, there is often a trade-off between cost and performance that manufacturers need to consider.

Printed Batteries and Their Potential Cost Benefits

Printed batteries represent a newer, emerging technology with the potential for cost-effective and adaptable energy storage solutions. As opposed to conventional batteries, printed batteries are created using inkjet printing techniques, enabling the production of tailored shapes and sizes. This attribute is handy in more compact applications.

The cost benefits associated with printed batteries arise from their scalable production process. The roll-to-roll process used can be automated leading to high throughput and low manual labor costs. Additionally, the flexibility in design allows printed batteries to be integrated seamlessly into product packages, potentially reducing product design and assembly costs.

Nonetheless, the current challenges lie in the less mature technology of printed batteries, especially in energy density and longevity, which are important for applications like EVs. As these technological challenges are overcome, their scalability and design flexibility make printed batteries a potentially promising, cost-effective solution for energy storage.

READ: Do electric Cars Have Transmissions?

Battery Technology on EV Pricing

Electric vehicles (EVs) are the future of transportation as they have the potential to impact global energy consumption and greenhouse gas emissions significantly. Yet, the main obstacle to the widespread adoption of EVs is their initial cost, primarily driven by the battery system. This article will evaluate how advancements in battery technology influence the pricing of electric vehicles through a detailed examination of three case studies – Tesla, General Motors, and NIO.

Tesla's Battery Cost Reduction and Its Impact on EV Prices

Tesla, the frontrunner in the EV market, owes a significant chunk of its success to its innovative battery technology. The company's patented designs and the strategic decision to build a battery Gigafactory have disrupted the pricing dynamics of the EV market.

Tesla's battery system, which constitutes about one-third of the overall vehicle cost, is both cost and energy-efficient. As seen in its ' Battery Day ' event, the continuous research and development efforts towards its battery technologies have drastically reduced battery costs over the past decade. More specifically, Tesla has been focusing on lowering cobalt content - one of the most expensive components in a cell - while increasing energy density, thereby decreasing both manufacturing costs and the battery's overall weight.

The plunge in Tesla's battery costs directly impacts its EV pricing. Tesla’s Model S, for instance, has seen a significant price reduction since its launch - a trend largely attributed to decreasing battery costs. As Tesla ambitiously looks to produce a 'low-cost' electric car using its new, cheaper batteries, EV prices will likely fall below those of gasoline-engine cars within a few years, making EVs more accessible to the average consumer.

GM's Ultium Battery Technology and Its Effect on EV Pricing

General Motors (GM) is another pivotal player in the global EV market and its recently announced Ultium battery technology reflects the company’s commitment to electrification. GM's Ultium battery technology promises high energy density and fast charging capabilities, which improve the vehicle's driving range and overall performance.

The innovative architecture of this modifiable platform allows varying combinations of the battery and powertrain components, enabling vehicle diversity. Moreover, using less expensive and less rare metals coupled with high-density battery cells helps reduce costs.

This multipurpose, cost-effective Ultium battery technology allows GM to develop EVs at various price points, catering to different consumer segments. This approach will potentially lower the prices of its EVs, making them significantly more affordable and accelerating the transition to an all-electric future.

Impact of NIO's Battery Swapping Technology on EV Pricing

Chinese automaker NIO has taken a different approach to battery technology by offering a battery-swapping service. NIO's innovative Battery-as-a-Service (BaaS) model enables customers to purchase the vehicle without the battery (the priciest component of an EV), reducing the upfront cost. Subsequently, customers can lease and swap the battery at designated charging stations, offering more flexibility and convenience.

NIO’s strategy not only reduces the upfront cost of the vehicle but also alleviates concerns about battery degradation and technology obsolescence. As batteries' cost drops and efficiency improves, EVs will continue to become more affordable and attractive to consumers, further boosting global EV adoption.

All in all, these case studies clearly demonstrate that advancements in battery technology are instrumental in driving down EV prices, enhancing their appeal, and enabling a mass-market shift towards cleaner, electric transportation.The cost of electric vehicles (EVs), and the impact of battery life cycle costs on these prices, is a significant concern for many potential buyers. Despite the environmental and eco-benefits attached to owning an electric vehicle, one worry that often surfaces is whether the savings on fuel expenses outweigh the total cost of the vehicle, particularly when the costs associated with the life cycle of the battery are taken into account.

The Link Between Battery Life Cycle and EV Cost

To have a comprehensive understanding of EV pricing, it's crucial to understand the link between the battery's life cycle and the cost of the electric vehicle. A battery's life cycle is broadly described by the time it takes from the point of production until it needs to be replaced or disposed of. This life cycle largely influences the overall cost of an EV.

The production of an EV battery is a costly and energy-intensive process. It includes the mining of raw materials, followed by the manufacture and assembly of the battery. An electric vehicle’s battery is the most expensive part of the car and can be between 25% to 40% of the total cost of the vehicle. As a result, longer battery life can considerably affect an electric vehicle's overall cost and maintenance.

Moreover, the battery's life expectancy can significantly affect the car's depreciation value. A longer-lasting battery will lead to a higher resale value, making it more cost-effective from an ownership perspective. In addition, the charging frequency also contributes to the wear and tear of the battery, thus affecting its life span. Charging the battery only when it is nearly drained and keeping the charge between 20% and 80% can prolong the battery life cycle, facilitating a more budget-friendly ownership experience.

Cost Implications of Battery Replacement and Recycling

Eventually, all batteries, regardless of how well they are maintained, will decrease in efficiency. The battery's capacity reduces with time, leading to diminished vehicle performance and driving range. When the battery pack fails or cannot hold enough charge for adequate performance, the inevitable battery replacement cost is a significant concern for EV owners.

While EV battery costs have decreased over the years due to technological advancements and economies of scale, replacing the battery is still a significant expense. Therefore, incorporating these costs into the ownership experience is crucial when calculating the total cost of an electric vehicle.

On the upside, the recycling industry for lithium-ion batteries, commonly used in EVs, is growing. Developments in battery recycling technology offer the potential for revenue from used batteries. Policies and practices regarding battery recycling can dramatically influence the lifecycle cost of the battery. Many companies are investing in recycling, which is good for the environment and may help offset replacement costs in the future. For consumers, this could mean lower EV costs and higher return on investment over the vehicle's life cycle.

Understanding the entire life cycle of an electric vehicle, particularly the battery, is crucial when considering the purchase of an EV. The upfront cost of an electric vehicle can be higher than comparable petrol/diesel cars. Still, the long-term savings can be significant, primarily when the battery's life cycle cost is considered.

Effect of Battery Performance on EV Pricing

Understanding the effect of battery performance on electric vehicle (EV) pricing is essential for both manufacturers and consumers. As the core component of EVs, the battery largely determines the vehicle's overall performance, including its range, efficiency, and charging time. Moreover, the production cost of the battery is the key factor influencing the price of EVs, accounting for a large proportion of the total vehicle cost. Therefore, improving battery performance can enhance EVs' competitiveness and reduce their prices.

How Battery Efficiency Influences EV Price

Battery efficiency refers to how effectively a battery converts the stored chemical energy into electric energy for vehicle use. If the battery of an EV has high efficiency, more energy can be provided for driving, thus improving the vehicle's performance and making it more attractive to potential consumers. However, enhancing battery efficiency usually requires investment in advanced technologies and materials, which can substantially increase the production cost of the battery.

Therefore, the price of EVs with high-efficiency batteries tends to be higher than those with low-efficiency ones. Consumers have to pay a premium price for better performance, but they can also benefit from reduced energy consumption and, therefore, lower operating costs in the long term.

Impact of Battery Range on EV Pricing

The range of an EV, which refers to the maximum distance that the vehicle can travel on a single charge, is another crucial factor that influences both the performance and price of EVs. A longer range usually indicates that a larger and more powerful battery is used in the EV. While this can alleviate the so-called ‘range anxiety’ among potential consumers and enhance the vehicle's competitiveness, it also increases the production cost of the battery and, therefore, the price of the EV.

As a result, EVs with long ranges tend to be more expensive than those with short ranges. Nonetheless, as technology advances and economies of scale are realized, the price of long-range EVs is expected to become more affordable.

Effects of Battery Charging Speed on EV Pricing

Battery charging speed, or the time it takes for a battery to be fully charged, also plays a crucial role in determining the price of EVs. Consumers highly value fast charging capability as it significantly saves time and increases convenience. However, the development of fast-charging technologies and systems is complex and costly, involving the battery itself, the charging infrastructure, and the on-board charging hardware. Therefore, EVs with fast-charging capabilities often come with a higher price tag. Meanwhile, fast charging also means more frequent replacement of batteries, which can lead to higher lifetime costs for consumers. Despite these costs, the convenience and time-saving benefits of fast charging are important factors that make EVs an appealing choice for consumers.

The role of government institutions in shaping market dynamics cannot be understated. Their policies, guidelines, and mandates directly control the pace and trajectory of technological progress and economic development in a given sector. The battery technology industry is no different. This section seeks to dissect in real terms, the influence and impact of government policies on battery technology evolution, particularly in terms of production cost and innovation.

Influence of Government Subsidies on Battery Production Cost

Subsidies, tax incentives, and other forms of financial support offered by government institutions have become vital to the growth and sustainability of the battery production industry. Many governments globally incentivize battery production to lessen their countries' dependence on fossil fuels, reduce greenhouse gas emissions, and move closer to a more sustainable, carbon-neutral future. Subsidies play a crucial role in reducing the high initial cost associated with producing batteries, particularly lithium-ion batteries, which are common in electric vehicles and renewable energy systems.

For instance, the Chinese government provides a web of subsidies to its battery manufacturers, reducing the domestic market price of lithium-ion batteries and catalyzing a significant increase in their production. This surge in manufacturing realized economies of scale, further driving down costs. The American and European governments have adopted a similar approach through offering tax incentives to manufacturers and purchasers of electric vehicles. This initiative indirectly stimulates demand for lithium-ion batteries, prompting increased production and lower costs.

At a granular level, these subsidies influence the decision-making process of manufacturers. Producers are more likely to invest in R&D, new production machinery, and qualified human capital when they have the assurance of reduced financial risk provided by subsidies. This government-industry cooperation has been instrumental in steering the battery technology industry toward a more competitive, innovative, and cost-effective future.

Impact of Regulatory Policies on Battery Technology and Costing

Government regulatory policies can either be a boon or a bane for the battery technology industry. Stringent regulations in terms of safety standards, waste disposal, or recycling can increase the overhead costs of production, which may indirectly influence the market cost. Similarly, the mandates on CO2 emissions may compel battery manufacturers to invest in cleaner but more expensive production methods.

However, regulatory policies can also offer a path for innovation in battery technology. For instance, regulations such as the End of Life Vehicles Directive by the European Union have led to developments in recycling technologies for batteries. Battery manufacturers are compelled to innovate and produce batteries that are not only efficient and cost-effective but also environmentally responsible.

The evolving nature of regulatory frameworks and the dynamic nature of battery technology innovation ensure that manufacturers constantly adjust their prices to maintain profitability while staying compliant. Therefore, it is safe to conclude that government policies, both financial and regulatory, significantly influence battery technology, from its manufacturing cost to its market cost and usability.

The Role of Market Forces on Battery Technology and EVs

Market forces, particularly supply, and demand, play a crucial role in shaping the future of battery technology and electric vehicles (EVs). The continual innovation and endorsements from major companies worldwide have led to a rapid surge in consumer interest and demand for these technology-driven vehicles. However, the battery technology that drives these vehicles remains restraining, illustrating the influence of market forces in this industry.

Market Competition and Innovation in Battery Technology

The world has witnessed relentless advancements in battery technology in the past few decades. Drivers of innovation often stem from market competition among companies intending to provide top-notch products to consumers for market leadership. Here, market forces like competition fuel the technology research and development race by creating a sense of urgency among manufacturers to innovate and improve the batteries' effectiveness continually.

Moreover, since battery technology is a critical driver for EVs, the manufacturing industry focuses on producing batteries that offer more extended travel range, faster charging times, and are environmentally friendly, amongst other advanced features. The competition doesn't stop at manufacturing, as firms also aim to innovate in terms of cost-effectiveness, thereby making EVs more accessible more quickly. This pattern has created a fertile ground for innovation that has accelerated the development of battery technologies. Yet, this market-driven innovation is not without challenges. It necessitates heavy investments in research and development, cutting-edge machinery, and skilled human resources.

Trends in Consumer Demand and Its Effects on Battery Technology and Pricing

Consumer demand is a key variable in free-market settings. As people grow more environmentally conscious and subsequently more interested in EVs, consumer demand for these vehicles has soared. People are consistently seeking vehicles that are not only environmentally friendly but also energy-efficient, with long driving range and minimal charging time.

This shifting trend in consumer behavior has significantly influenced the direction of battery technology. In response to the rising demand, manufacturers are pressured to develop high-energy-density batteries that charge quicker, last longer, and are affordable. This process of catering to consumer demand results in technological progress aimed at minimizing cost while maximizing performance. While less expensive lithium-ion batteries have ruled the EV market thus far, alternative technologies like solid-state batteries that promise better energy densities and range are emerging.

Another critical aspect influenced by market forces in battery technology pricing. As demand surges, manufacturers must ramp up their production, leading to economies of scale. This transition often leads to decreased prices per unit, making EVs more affordable for a wider consumer base and supporting the global switch towards a more sustainable transport solution.

In summary, market forces play an indispensable role in shaping battery technology and the rise of EVs. From influencing the pace of innovation to molding consumer demand and pricing strategies, these forces' impact is undeniably significant. As more and more companies and buyers embrace EVs, these market forces will continue to direct the future of this vital industry. In today’s technological and industrial advancements, battery technology plays a fundamental role, especially in the burgeoning electric vehicle (EV) market.

The broader impacts of battery technology encompass economic, social, and environmental aspects and cannot be overlooked. Battery technology is effectively reshaping and transforming the global EV market and by an extent, the future of clean energy mobility. This is an examination of how battery technology significantly influences the EV market and how this ultimately results in a myriad of benefits spanning several sectors of human life.

Ramifications for the Future of Clean Energy Mobility

The future of clean energy mobility mainly depends on battery technology advancements. With the advent of lithium-ion batteries, the global transition from internal combustion engines to electric vehicles has seen a remarkable acceleration. This is due to lithium-ion batteries' myriad benefits, including increased efficiency, longer lifespan, fewer emissions, and reduced reliance on non-renewable fossil fuels.

Current battery technologies are advancing at an unprecedented rate. The introduction of solid-state, graphene, and the continual improvement of lithium-ion batteries are gateways to even more efficient, longer-lasting, and safer electric vehicles. Notably, these advancements are reducing the charging times of EVs, thereby countering one of the major barriers faced by the sector in its early stages.

Technological leaps in the form of energy-dense batteries offer the possibility of extended ranges for electric vehicles, thereby making them more competitive with their petrol-powered counterparts. Enhanced range and speed, and reduced charging time, are all entailed in this upgrade of battery technology. The overall effect is a more user-friendly, practical, and efficient mode of transportation, marking significant progress towards a clean energy future.

READ: Which Motor Is The Best For An Electric Car?

Economic Impacts of Battery Technology Improvements

The evolution of battery technology drives a huge economic shift, fostering a new era of growth and investment opportunities in the global EV market. Due to technological advances and scaling of production, the decrease in battery costs has made electric vehicles more affordable, increasing their market appeal.

Moreover, the thriving EV sector, buoyed by improved battery technologies, is a significant job creator. It stimulates employment opportunities in various sectors, including manufacturing, research and development, installation, maintenance and services related to electric vehicles and their components.

It's also worth mentioning that the rise of the electric vehicle market has resulted in positive knock-on effects for associated industries. For instance, increased demand for electric vehicle batteries has driven growth in the lithium, cobalt and nickel mining sectors. Furthermore, renewable energy sources such as solar and wind require storage solutions, which are also provided by advancements in battery technology.

In conclusion, the rise of the EV market, driven by advances in battery technology, is not just an environmental success story. It is also an economic and social one, transforming industries, creating jobs, driving investment, and fostering technological innovation.

Therefore, it's clear that the role of battery technology in shaping the global EV market and the transition toward clean energy mobility is profound and multifaceted. As technological innovations push the boundaries, the world steadily moves towards a greener, more efficient, and economically robust future.